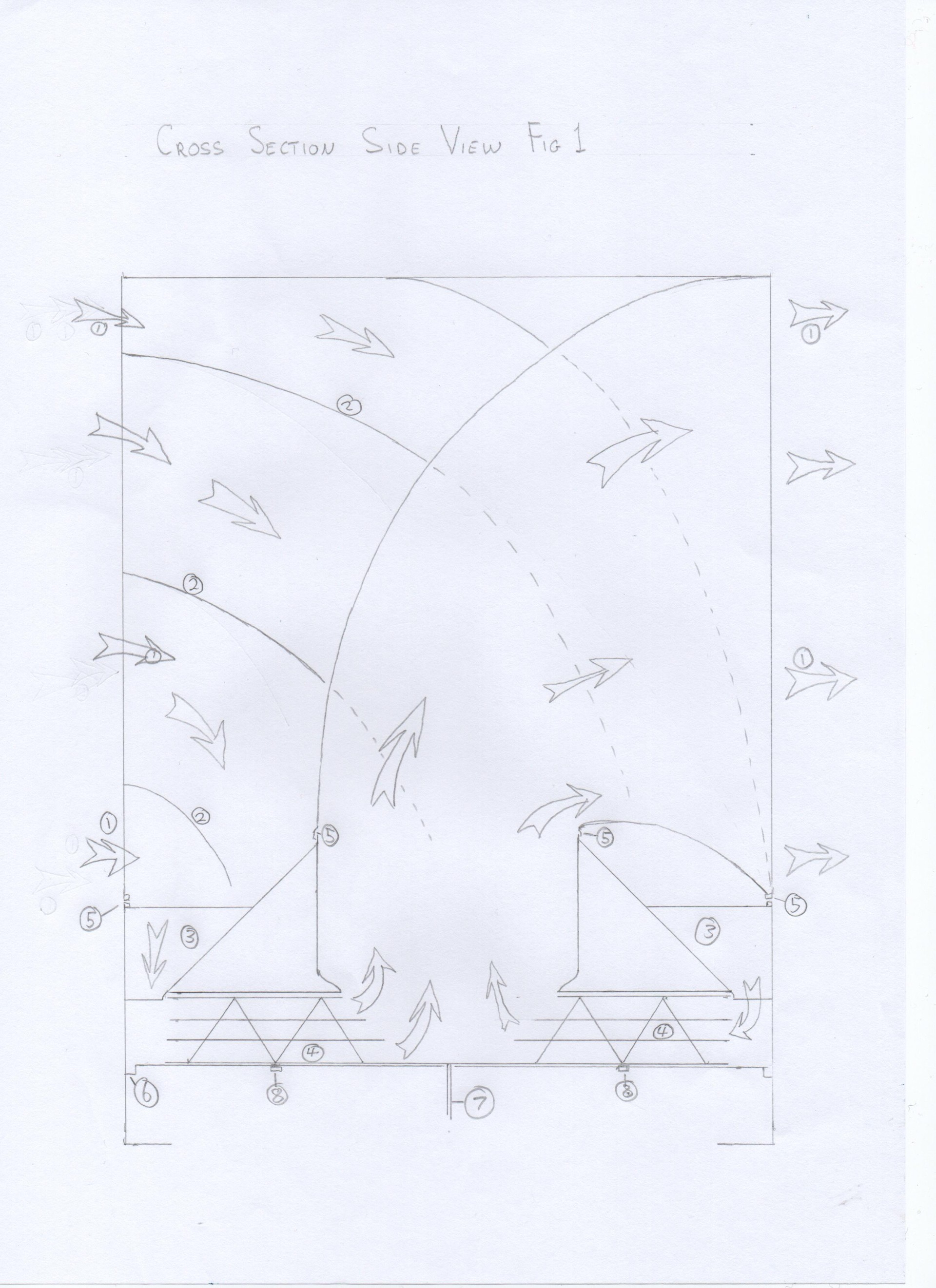

This innovative wind power system is designed to harness the power of nature to generate electricity at a cost below that of the grid. To this end the design focuses on making the maintenance costs extremely low and also has a low initial price compared to standard 3 bladed windmill type systems. So far I have built the prototype shown. I would like to present the experimental data showing wind speed and electricity generated, But as yet I don’t have the surprisingly difficult-to-buy sensors and recording equipment. I am also on a tight budget and don’t want to spend money on things that I don’t absolutely need. The idea is that the wind is directed down by the large rotatable cowel to director vanes which induce a spin in the air. This spinning air is then taken into the centrifugal turbine and out of the center of it. Exiting the cowel structure at the back to hopefully be sucked away by the wind flowing around the cowel.

As you can see this is a very Heath Robinson affair with lots of use of wood and scrap roofing material.

The market is reasonably large for a less than 6kW capacity wind turbine system which would provide electricity whenever the wind was blowing, for either places that wanted to save money or off grid applications. Systems larger than 6kW are considered industrial electricity providers and have a more complex relationship with the grid. One of the advantages of this system in such an application is the ability to work at high wind speeds. The finished product will have louvre shutters on the front, which can be throttled to slow the wind's entry into the system or the whole cowel can be rotated away from the wind. This is, in any case a far lesser problem for this centrifugal wind turbine as the radius of the spinning working parts is far less. Thus far less centrifugal forces to worry about.

I am hoping to find a suitable partner to work with to build the product for market. I look forward to discussing this with any interested parties.

My business plan is not there currently and I am very much hoping for any help and advice to move this forward.

And yes it is just me, Tim Grindley, with the prototype as seen in the videos taken in the UK.

How it works

3D Simulation

Videos

Gallery

Why we're better

Replacement

Standard 3 blade turbines are made of light high tech materials which are compressed when vertically up and stretched when they come down, leading to breakages from stress. When this happens they have to be replaced with a massive crane, 100 feet up in a windy place. Which, as you can imagine, isn't great.

Our turbines however, are simple catchment ducts built out of cheap steel under no dynamic changes of stress, with their gearing and electrical components stored on the ground for easy access. They can also be easily throttled and wont break until ripped from the hillside.

Resilience

Standard 3 blade turbines also have a limit to what they can produce so when wind speeds get too high they shut off. If wind speed is less than 10% optimal it produces 70% power and if it's 20% less it produces 50% power.

As our turbines are so secure there is little risk and therefore no top speed at all, which produces lots and lots of energy.

Plan

Our plan at the moment is to build a second prototype / first commercial design. Which we expect to sell at about 12,000 pounds with an output of six kilowatts when the wind speed is 20mph or more.

The formula is:

Where v is the velocity of the wind in m/s.

Patent number ; GB2578267

https://www.ipo.gov.uk/p-ipsum/Document/ApplicationNumber/GB1711328.3/8c4ca4b5-1e16-458e-a4c5-904b4b552ac0/GB2578267-20221116-Publication%20document.pdf